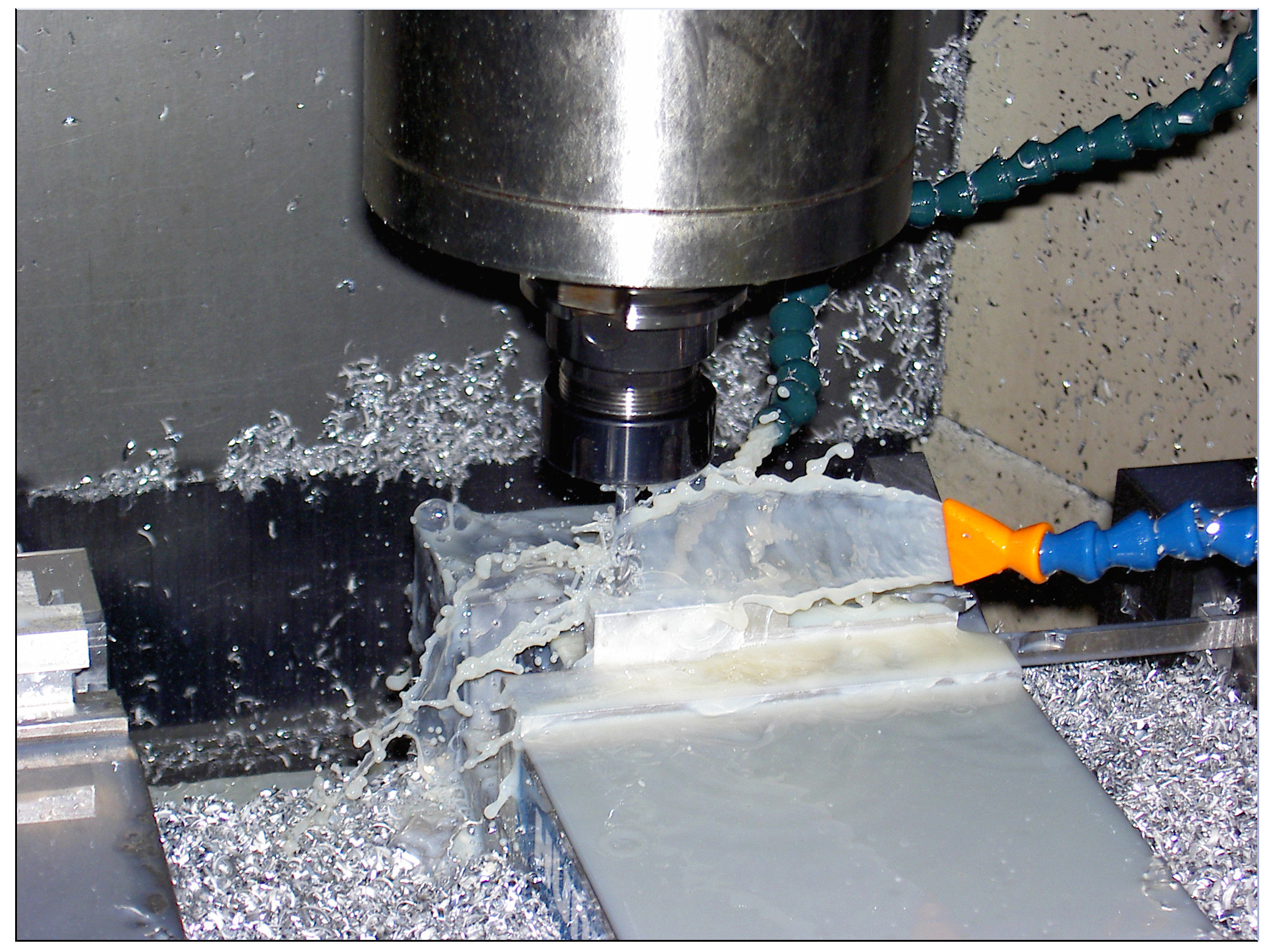

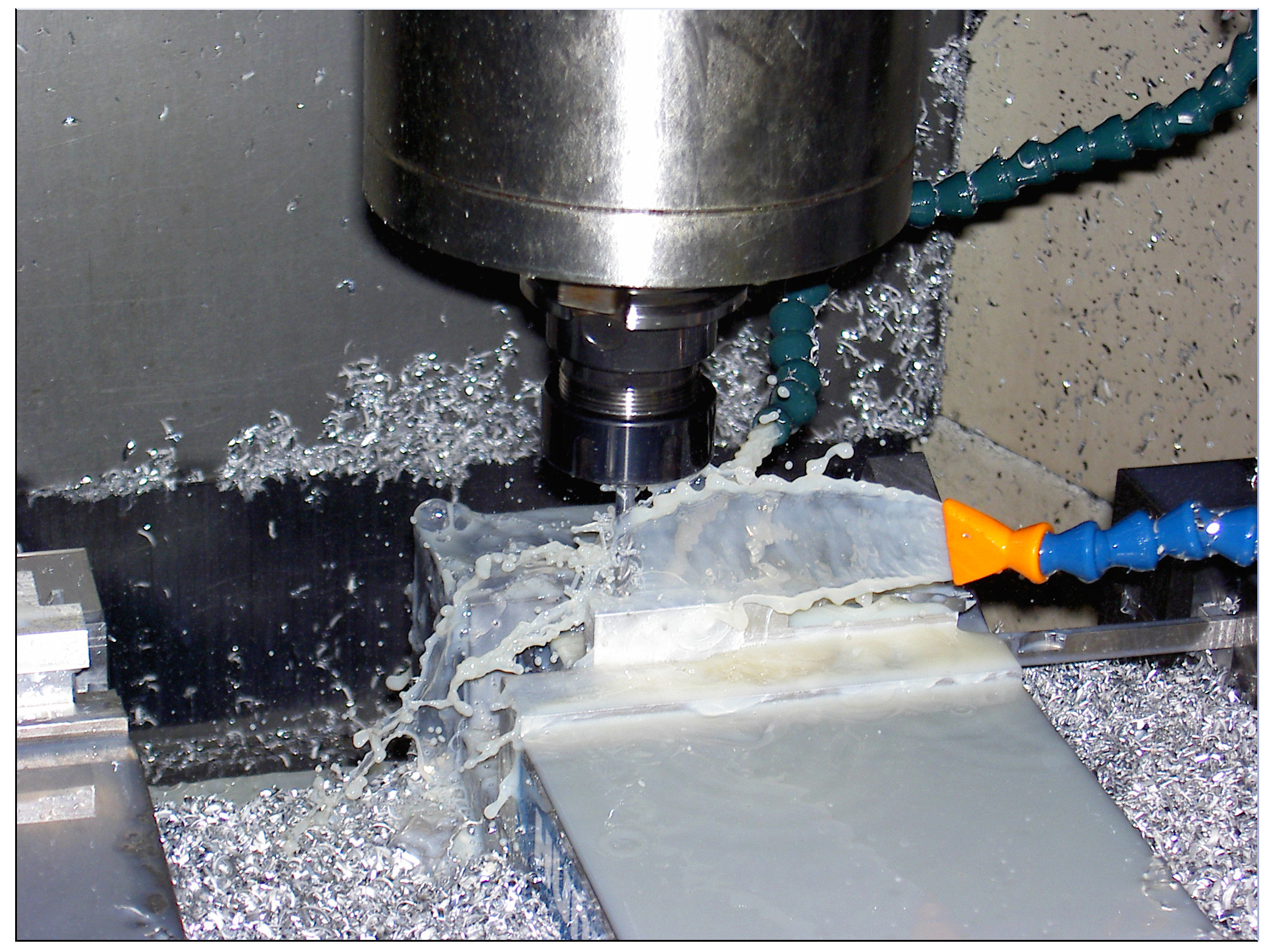

Milling

J & L Tool and Machine, Inc. utilizes CNC and Manual Machining Centers to produce a wide variety of parts from stainless steel, aluminum, titanium, brass and other materials. J & L’s machined parts are supplied to many industries including automotive, marine, and aerospace. In 2011 we purchased a VMX50 Hurco Vertical Machining Center. Our machining centers can handle material sizes up to 34″ X 64″ X 28″ (z axis).

Turning

At J & L Tool we use both CNC and manual lathes to produce parts and products made from all types of ferrous and non-ferrous metals, plastics, phenolics, nylons, and other materials. From smaller parts to larger diameter components and assemblies, J & L Tool can produce anything from prototypes to large production runs. In 2010 and 2011 we added 2 new lathes, a 50 HP Vertical Honor Seiki lathe with a 40” turning capacity and a Okuma CNC Lathe with live tooling. Manual lathes can handle up to 46″ diameter by 13′ in length.